Overall, this is a great All-in-one solution for beginners and hobbyists who don't want to learn multiple software for operating their CNC. It can be made to work with Marlin controllers but getting it to do so would require some tinkering.Įasel has a wide user base and a great online community at the Inventables Community forum.įor learning Easel you have the dozens of free tutorial videos provided by Inventables and also multiple YouTubers who make Easel tutorial videos. You can connect to your CNC machine via a USB cable and Easel works best with GRBL controllers. Using Easel does not require you to have any expertise in CAD/CAM software and is easy to use with a good user interface. However, this also means you need an active internet connection at all times to run Easel.Įasel has a monthly subscription fee of around $20 per month and a yearly subscription for around $13 per month.

Easy/cam cnc install#

You can create designs, convert them into G-Code and run your CNC machine with Easel.Įasel also has a pro version that lets you work on 4x8 workpieces, has more tool and design libraries and has the V-carve option.Įasel is web-based software and doesn’t require you to install any software and therefore, it can run on Windows and MacOS. The Easel software from Inventables is a truly all-in-one software which lets you do everything from CAD, CAM, and Control within a single software.

I have also categorized them so that its easier to understand what each software does.

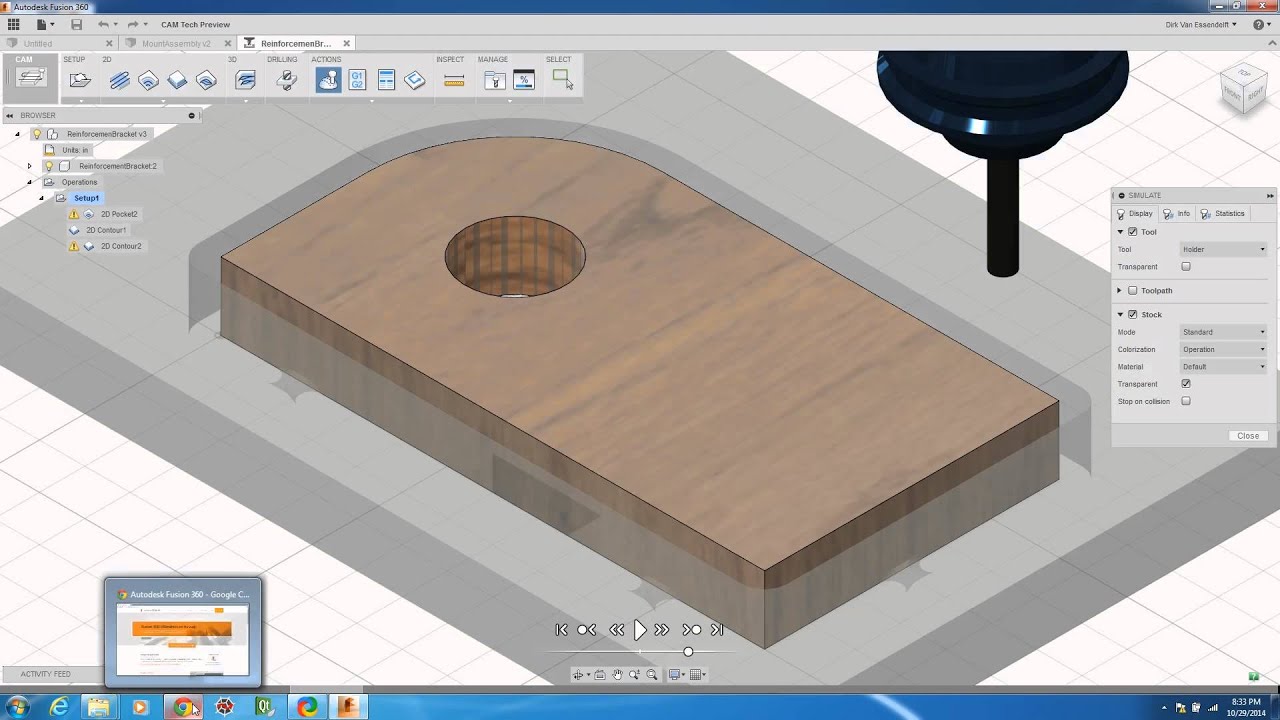

The free ones are mostly Open-Source CNC software. Some of these software are paid while some are free. There are dedicated software programs for each of these functions, but there are all-in-one software bundles that do everything as well.Īfter carefully considering the ease-of-use, reliability, compatibility, and community support, I have put together a list of some of the best software for your CNC application. However, many software programs can do more than one function among the four. Simulation software: reads the G-code and predicts errors that may arise while machining.Control Software: reads the G-code and creates signals to control the stepper motor drives.Computer-Aided Machining (CAM) software: Converts the designs to G-code, a language understood by machines.Computer-Aided Designing (CAD) software: Creates 2D, 2.5D or 3D designs.In a CNC machining process, there are four kinds of software involved. Here I walk you through all the best software choices for CNC routers and explain the advantages and disadvantages of each. I wanted to figure out how these software programs worked and which software was best for a particular purpose (like hobby CNC and Production CNC work). When I first stepped into the world of CNCs, I was overwhelmed by the many software programs used in the process.

0 kommentar(er)

0 kommentar(er)